Venture Force Global (VFG) has been operating in BPO Industry as a sustainable business for the last 14 years serving off-shore, on-shore, and near-shore clients in the USA, UK, UAE, and Pakistan. After spending more than a decade in Industry, VFG has observed a wide gap in the market concerning maintenance management of the industrial assets. Industries are massively disorganized and un-automated in the domain of Maintenance Management. After realizing the call for attention, VFG established a division for “Industrial Automation” to focus on Industry 4.0.

From the platform of VFG Industrial Automation Solutions, we find ways to guide different industries on how they can be converted from conventional industry to automation based or IIoT based Industries. Hence, our R&D team did research on the problematic areas of different industries and identified the major cause of unnecessary downtimes. From all the research which has been done, it is found out that the major causes of Plant Downtime are problems occurred in motor and pumps (Insulation breaking, Shaft imbalance, Misalignment, Wear, Rotor imbalance, Rotor bar faults, Loose rotor, Eccentricity) and Stator (Stator looseness, Incorrect air gap, Winding fault, Motor bearing housing, Mechanical looseness, Misalignment). In order to avoid the above causes, these equipment need attention every once in a while. We also acquired exposure that most of the mechanical equipment including the bearings and dodge gear reducers often require maintenance.

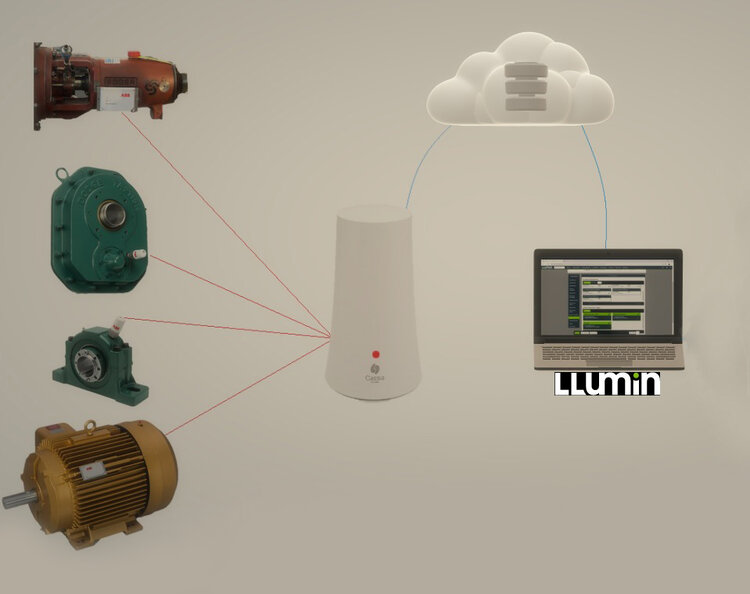

We have partnered with solution providers and integrators and created a Project and Engineering team. VFG Industrial Automation Solutions along with ABB provide different sensors including (ABB Smart Sensor for motors, pumps, bearings, dodge gear reducers, and also for different mechanical equipment). These sensors will convert conventional industries to the pattern of Industry 4.0. Consequently, it will transform preventive maintenance into predictive maintenance. The sensors will be mounted on motors, pumps, and mechanical equipment, from where the data will be sent to the cloud. It includes Health Parameters (Overall vibration, Bearing conditions, and Skin temperature) and Operational Parameters (Vibrational radial, Vibrational tangential, Vibrational axial, Speed, Number of starts between measurements, Motor supply frequency, Output power, signed speed, Kurtosis (X), Peak to Peak (Z), Total running time, Total number of starts). The ABB Smart Sensors acquire data due to vibration and temperature change and do predictive analysis using ISO Standards as reference. The sensors can also provide certain trends and graphs on real-time monitoring predictive analysis including graphs of temperature, vibration, and bearing conditions.

After the acquisition of data from the sensors and the predictive analysis calculated by the sensors, it was also required that the relevant data should be sent to the concerned department to the concerned personals i.e. Department Heads, Service Engineers and Service Technicians. For that VentureForce Global Inc. has also partnered with LLumin. LLumin has been developed to be a smart integration of an EAM (Enterprise Asset Management Software) and a CMMS ( Computerized Maintenance Management Software) which has a module of machine interface, which enables the software to communicate with the controllers (PLCs, DCSs and SCADA systems) and Smart IIOT based Sensors. Performing Real-Time Condition Monitoring of Plant Assets and notifying the workforce about the status of Plant Asset.

The connectivity between the LLumin Software Suite and ABB Smart Ability Sensors has now been developed and now the industrial assets containing motors, pumps, bearings, dodge gear reducers, and also different mechanical equipment for operations can be monitored by the integrated system developed by connecting LLumin with ABB Smart Sensors for data acquisition and analysis. The protocols (OPC-UA, OPC-DA, and MQTT) were used by which the data will be sent to the Cloud. The purpose of sending this data (parameters) to the Cloud is to convert these industries into Industry 4.0 patterns that will dramatically reduce the downtime and help enterprises optimize the performance of their assets, streamlines the management of critical materials, and ensure compliance with regulations. The industries will acquire more benefits from the LLumin Asset Management Software because it provides Asset Management, Work order management, Data Collection, and Assets Condition Assessment, Asset capital planning and risk Assessment, 3D View Facility. Similarly, it also facilitates different industries through Machine Interface, Arc GIS, eCommerce, Augmented Reality, and Fleet Telematics Interface. On the contrary, LLumin also provides management through Report and Analytics, Dashboarding, User Management, Configuration, and Customization.